Automotive Technology

To guarantee the highest quality, WPM Leipzig offers you as manufacturer of cars or supplier specifically adapted testing technology.

To guarantee the highest quality, WPM Leipzig offers you as manufacturer of cars or supplier specifically adapted testing technology.

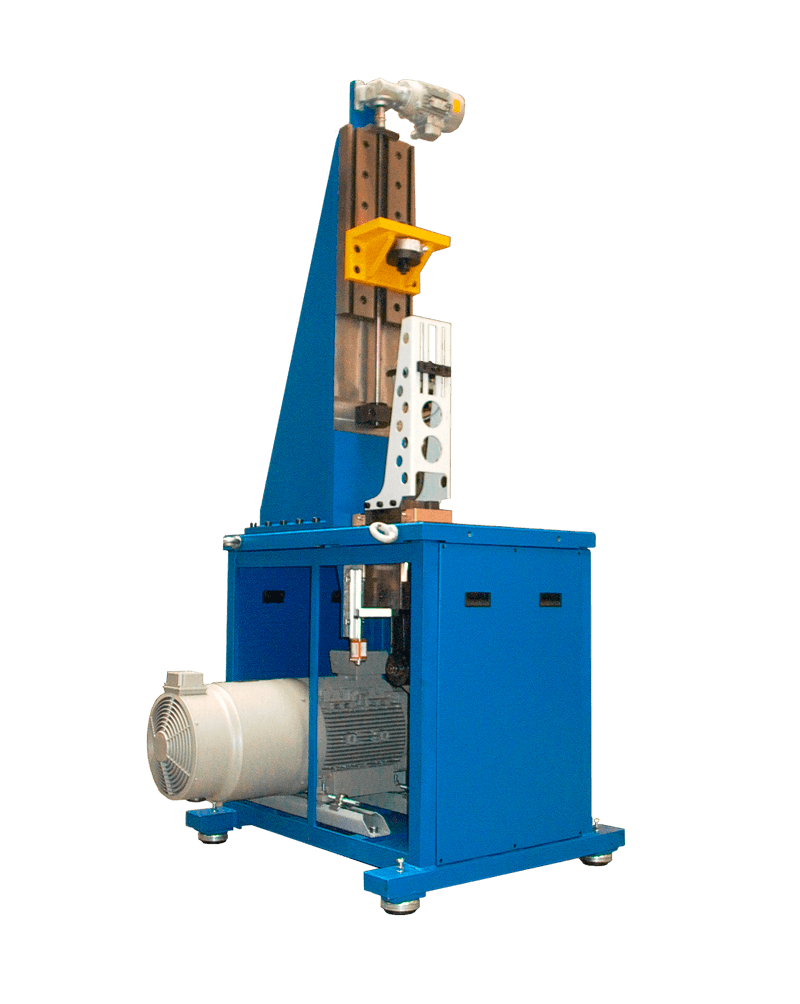

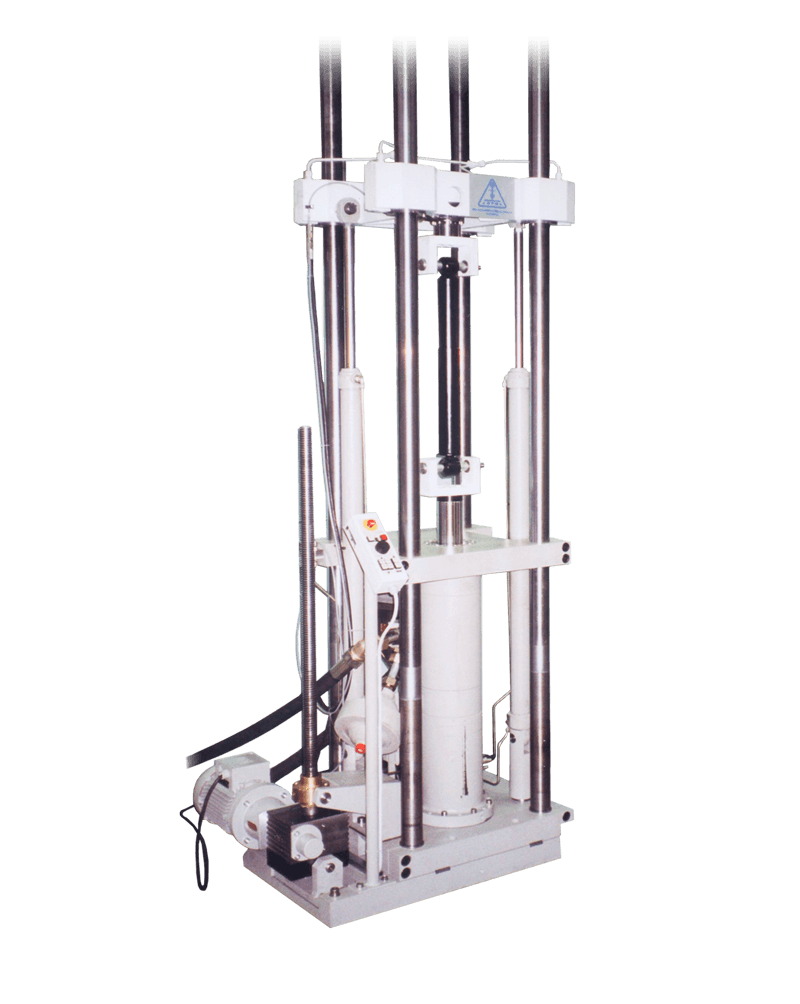

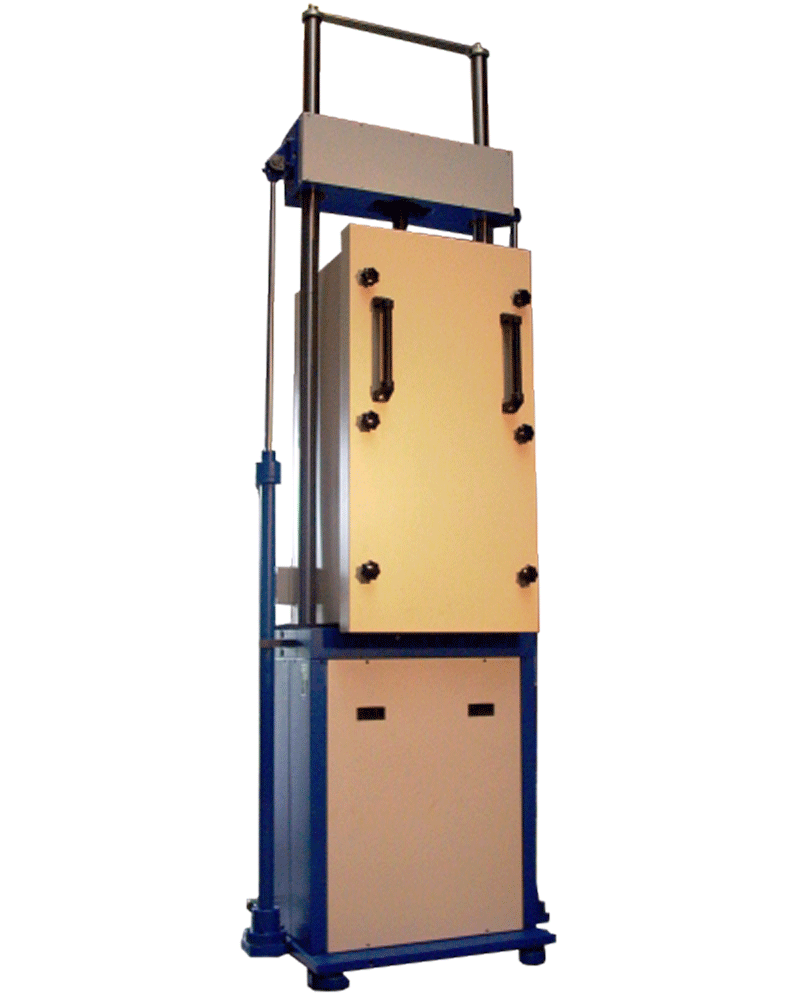

WPM Leipzig offers shock absorber test rigs with servo-hydraulic or electromechanical drive for dynamic tests of shock absorbers. The measurements are acquired and evaluated with displacement, force and speed.

The test rig consists of a machine frame of two columns with

By means of an operating panel at the machine frame, the cross head and the position of the piston stroke are adjusted manually. The shock absorber test is carried out in vertical position of the machine frame.

The shock absorber is fixed at the testing cylinder piston and at the force transducer by means of a bifurcate fixing with bolt receivers for the corresponding size of the shock absorber.