Modernization

Professionally and adapted to your requirements

Professionally and adapted to your requirements

If your testing machine or rig (e.g. of VEB Werkstoffprüfmaschinen Leipzig before 1990) is mechanically working well, but the control and evaluation system is obsolete or does not meet your demands anymore, we solve your problem – by our professional modernization!

We not only modernize testing machines of WPM Leipzig, but also non-WPM products and we only use components and assemblies from well-known manufacturers, considering your special requirements.

You save up to 60% of the costs in comparison to buying a new machine!

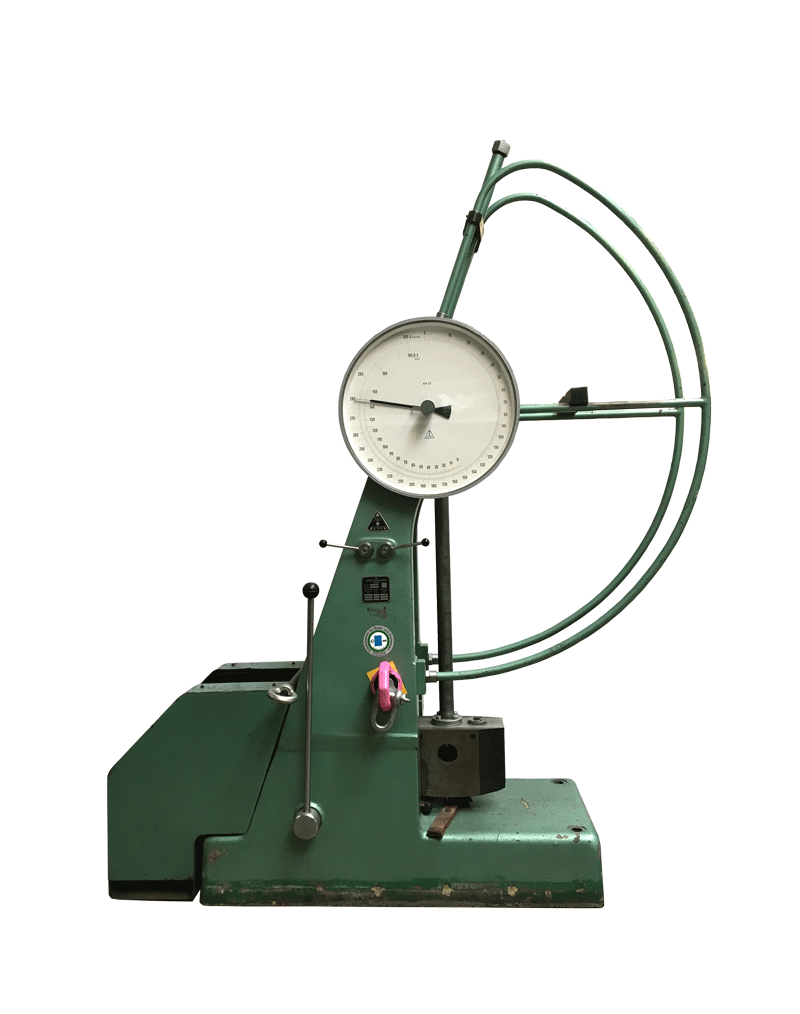

Pendulum impact tester PS 30 before modernization

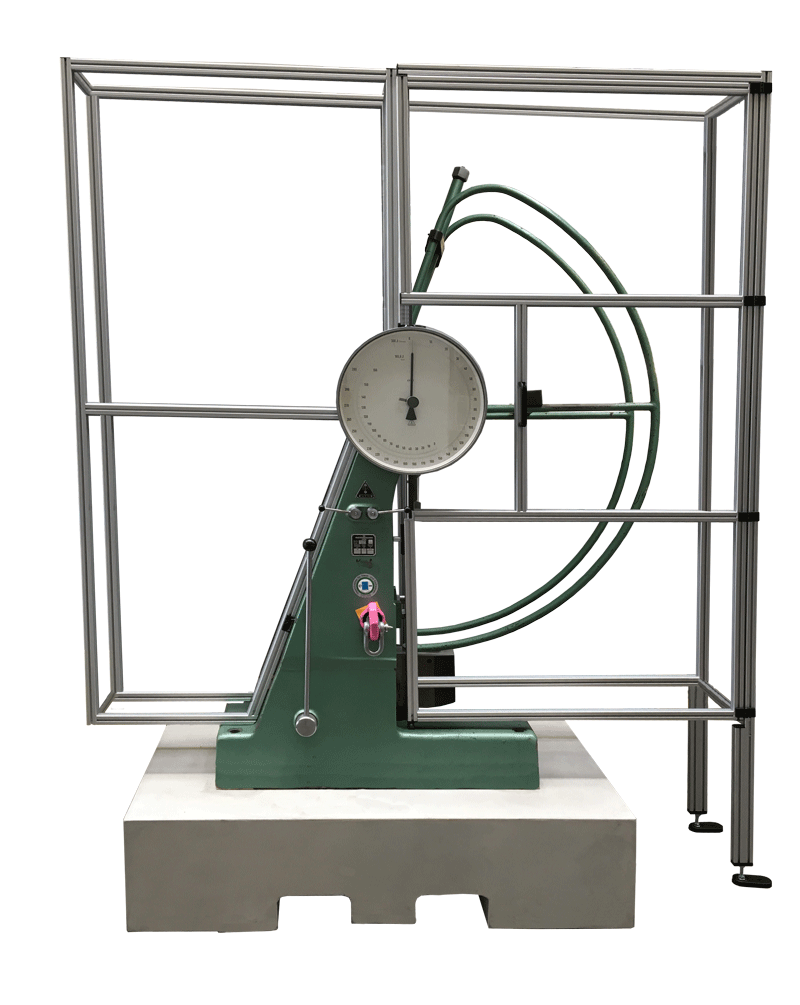

Pendulum impact tester PS 30 with enclosure and concrete foundation

Older pendulum impact testers, e.g. PSW 300 or PS 30, can be upgraded by Kögel to meet the safety requirements of the Machinery Directive 2006/42/EC and DIN 51233. Thanks to this safety upgrade, a CE sign can be added to the pendulum impact tester.

Depending on the model, the following components and options for the upgrade are available:

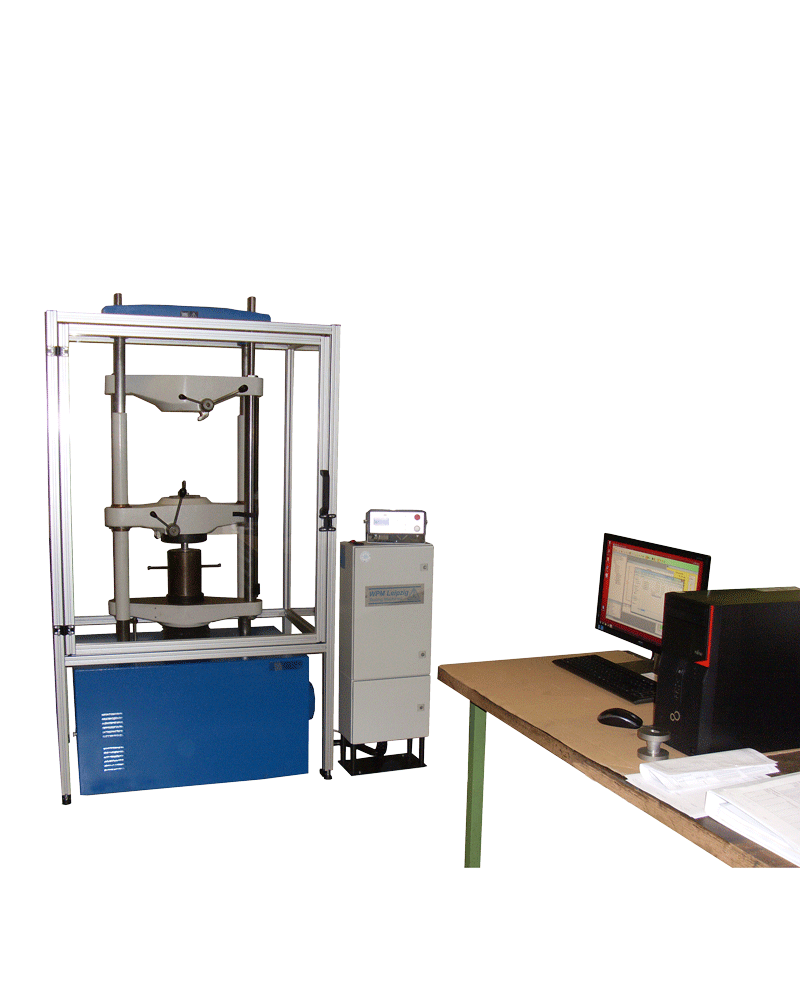

Modernized EU 40

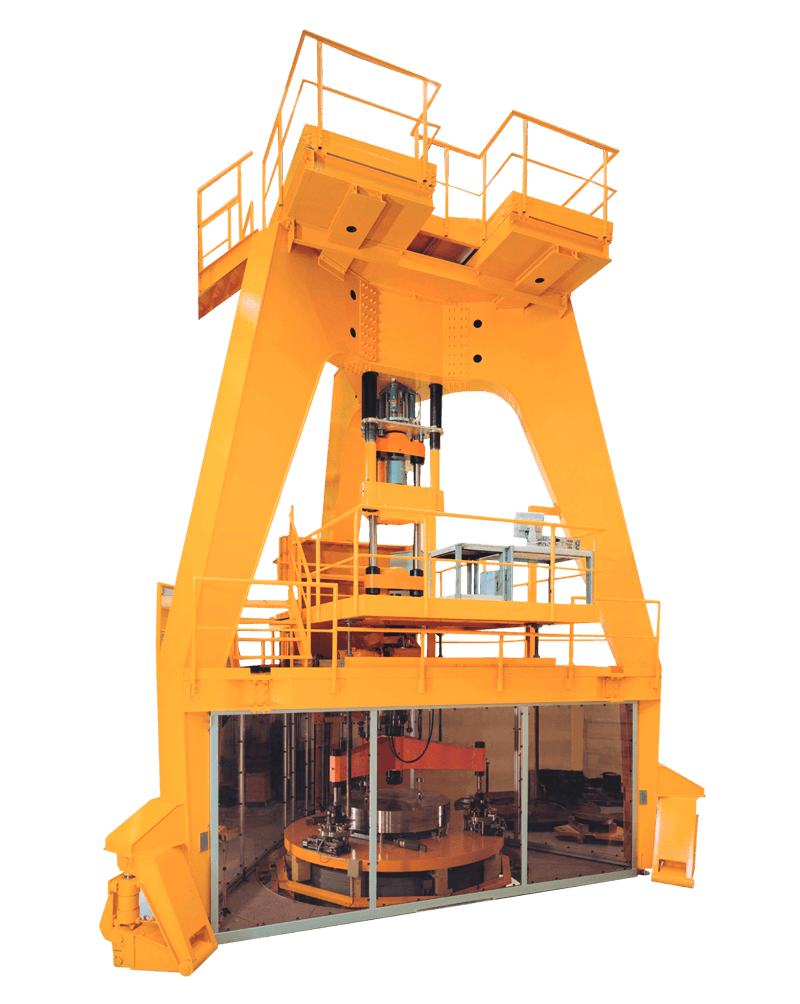

Modernized 2 MN deadweight force standard machine

By modernizing your testing machine, alle requirements according to EN ISO 7500-1 concerning force measurement unit and EN ISO/IEC 17025 concerning calibration and testing possibilities are fulfilled. Individual adaptations for your test tasks are possible.

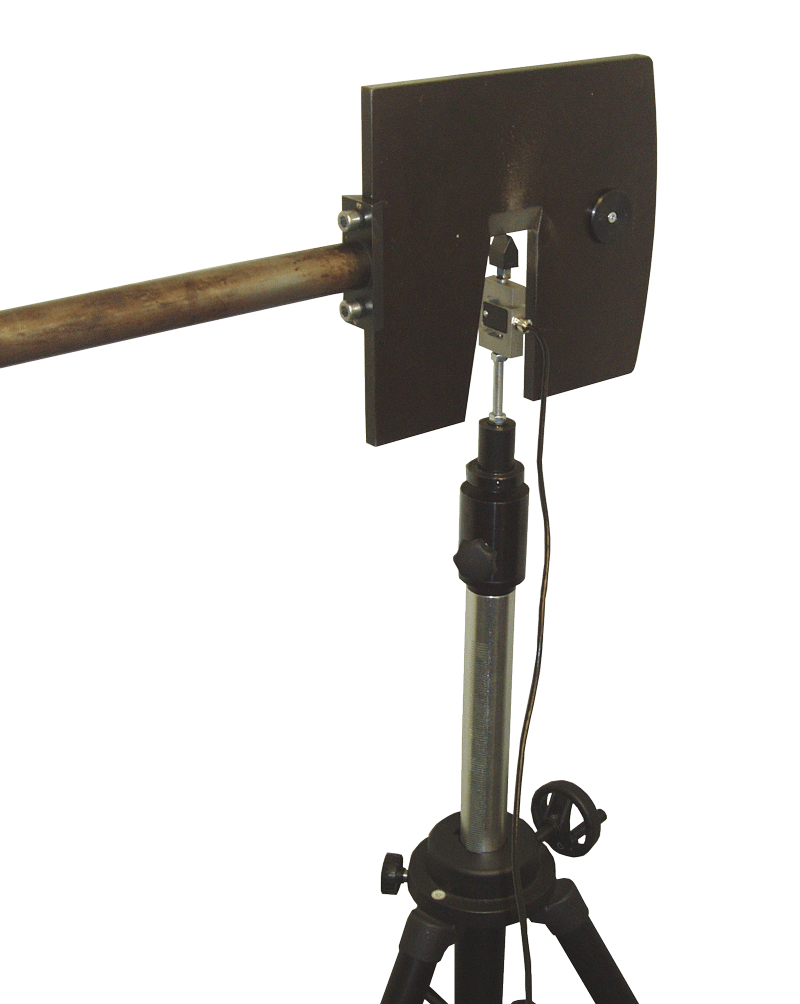

Modernized Rockwell hardness tester HP 250

The hardness testers of VEB Werkstoffprüfmaschinen Leipzig, Karl Frank GmbH and other manufacturers are robust and widely used devices. By means of a modernization, we bring these devices up to the cur-rent state of the art. This gives you a modern, reliable and future-proof hardness tester that can still be calibrated.

With the digitalization box, Rockwell hardness testers such as HP 250, HM 1810 and HM 1830 can be digitized and modernized. Brinell/Vickers devices, such as the HPO 250, can also be digitized in conjunction with a digital caliper.

The digitalization box replaces your old measuring system and meets the requirements of the current standards ISO 6508 and ISO 6506. With this conversion, you can continue to test in accordance with the standard with your hardness tester. For Rockwell devices you achieve a measurement accuracy of 0.05 HRC.

The digitalization box also contains an interface for data transmission, which enables the measured values to be transmitted directly to third-party systems for data acquisition and analysis. To do this, the measurement data is exported from the digitalization box to your Excel template, which you can then evaluate there. This allows you to digitally store and process your measurement data in order to optimize the quality of your test processes.