Customized Testing Machines

Here you can find further examples for innovative testing and measuring machines lately designed and built.

Here you can find further examples for innovative testing and measuring machines lately designed and built.

The mechanic shock test bench allows examining components and modules with shocks. The shocks imitate in a simple way the stress for example occurring during transportation.

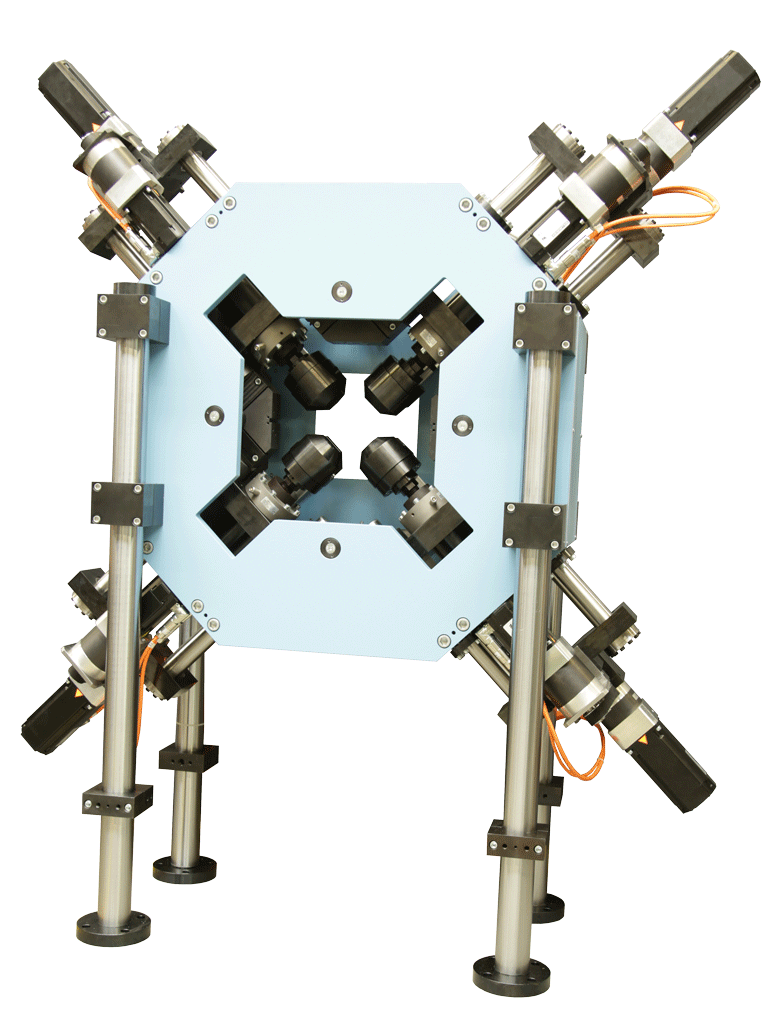

The biaxial testing machine is an electro-mechanic testing machine to carry out uni- and biaxial tensile tests with normal test specimen or cross specimens according to ISO 16842. The testing machine makes it possible to generate independent loadings at cross-shaped specimens of metal in two axes orthogonal to one another. So, it is possible to simulate biaxial distortion conditions, for example occurring with typical sheet metal forming.

The two orthogonal axes consist of two opposite single drives each.

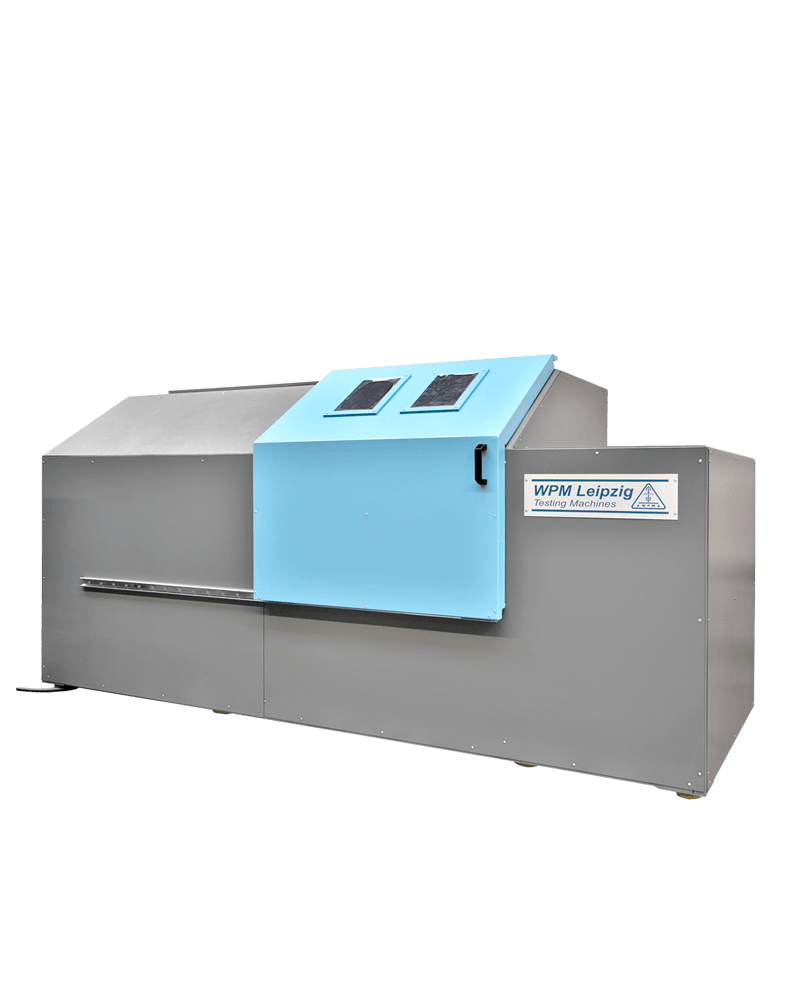

The PVR-400/400 rig serves to carry out a programed deformation-disruption-test. The PVR test was developed as a technological procedure to determine the susceptibility of disruption at high temperatures of basis material and filler metals with high quantitive validity concerning the influence of the component following Prokhorov’s theorem.

With a resurface welding on a plane specimen is overlaid with an increasing tension speed in welding direction with applying a tension force at the same time.

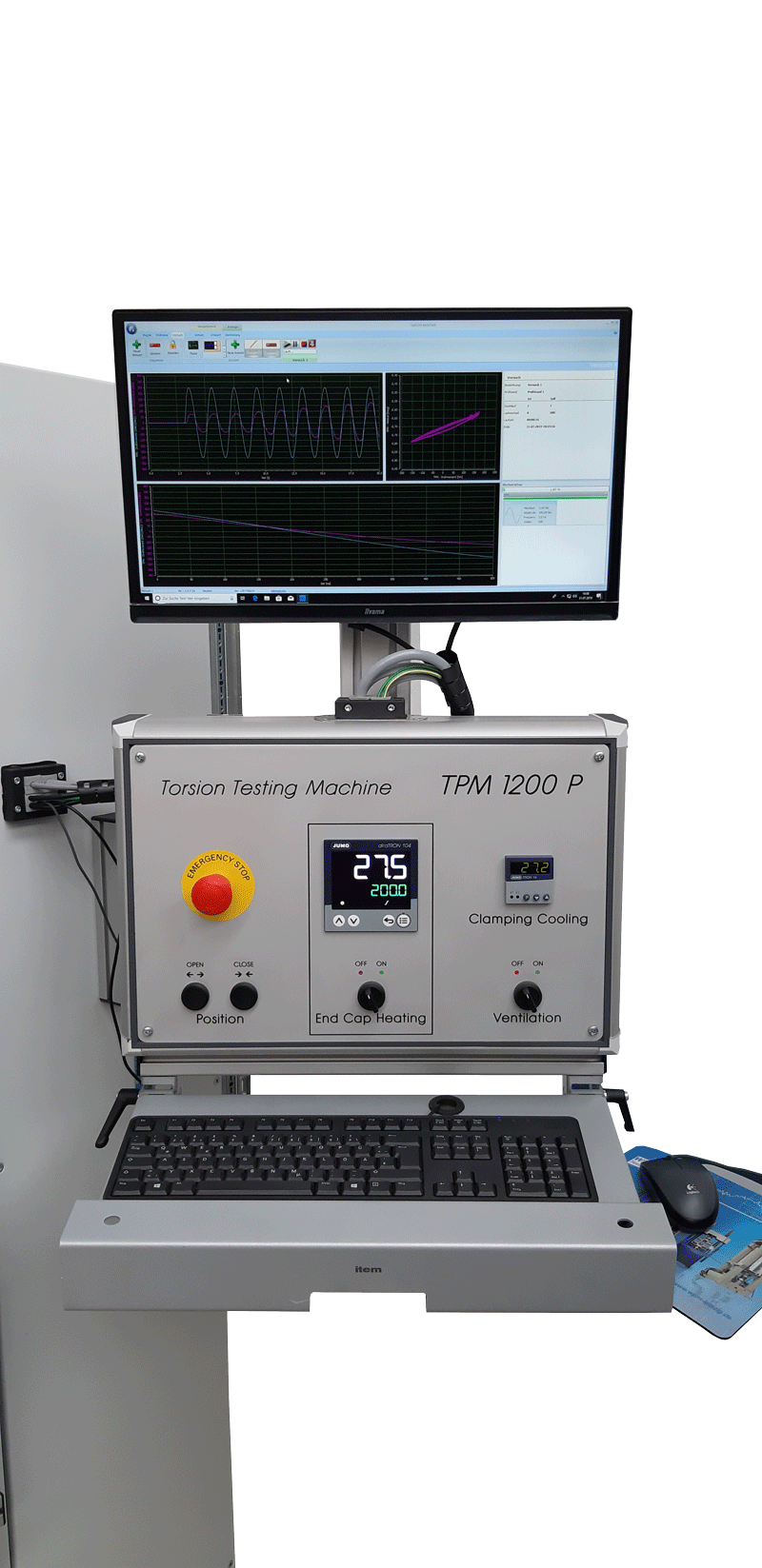

The testing rig serves to determine the static torsion resistance and service life under variable load at assemblies of ceramic fused silica rolls/pipe ends with a metallic mating part.

The tests can be carried out with temperatures from room temperature to 300°C.

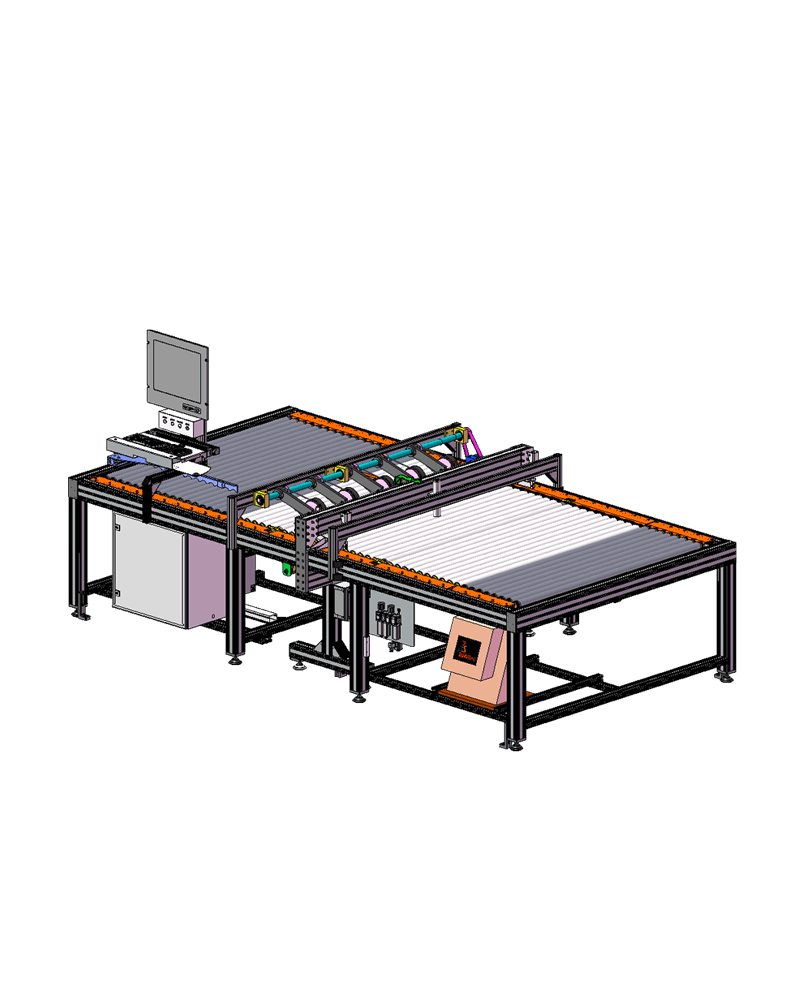

The measurement machine for thickness DMP-15 was developed to measure plates out of plastic with the following qualities: