Application

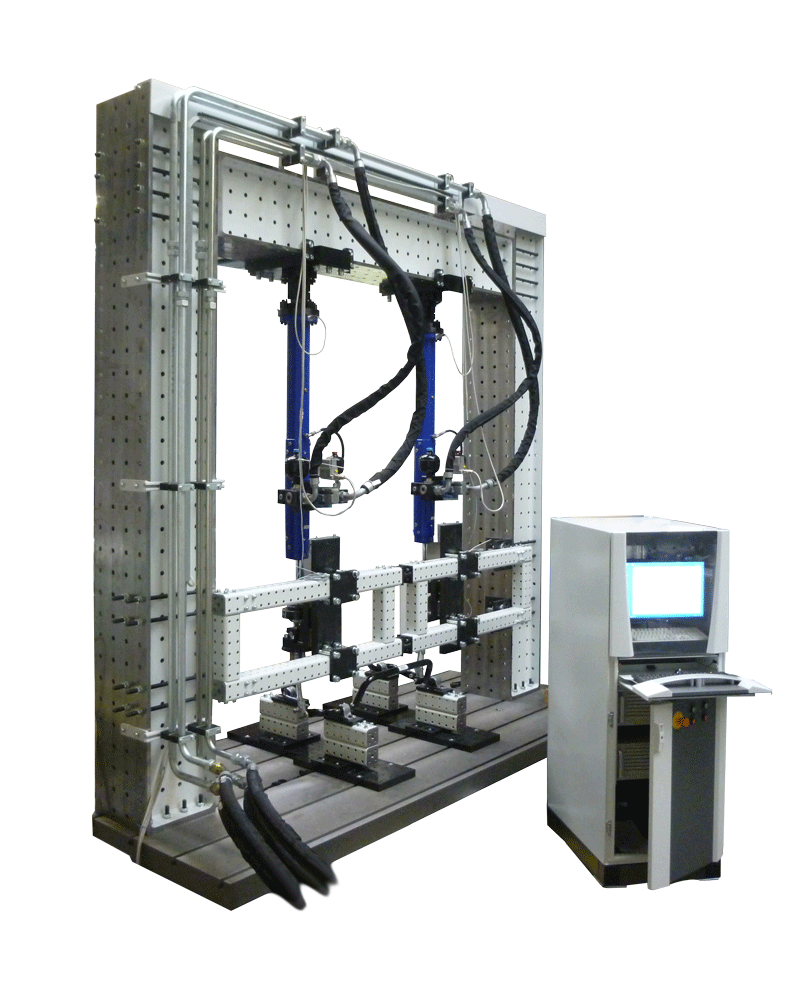

The test rig for automobile stabilizer bars is mainly used with dynamic fatigue tests of automobile sway bars.

Features

The testing rig consists of the following functional modules:

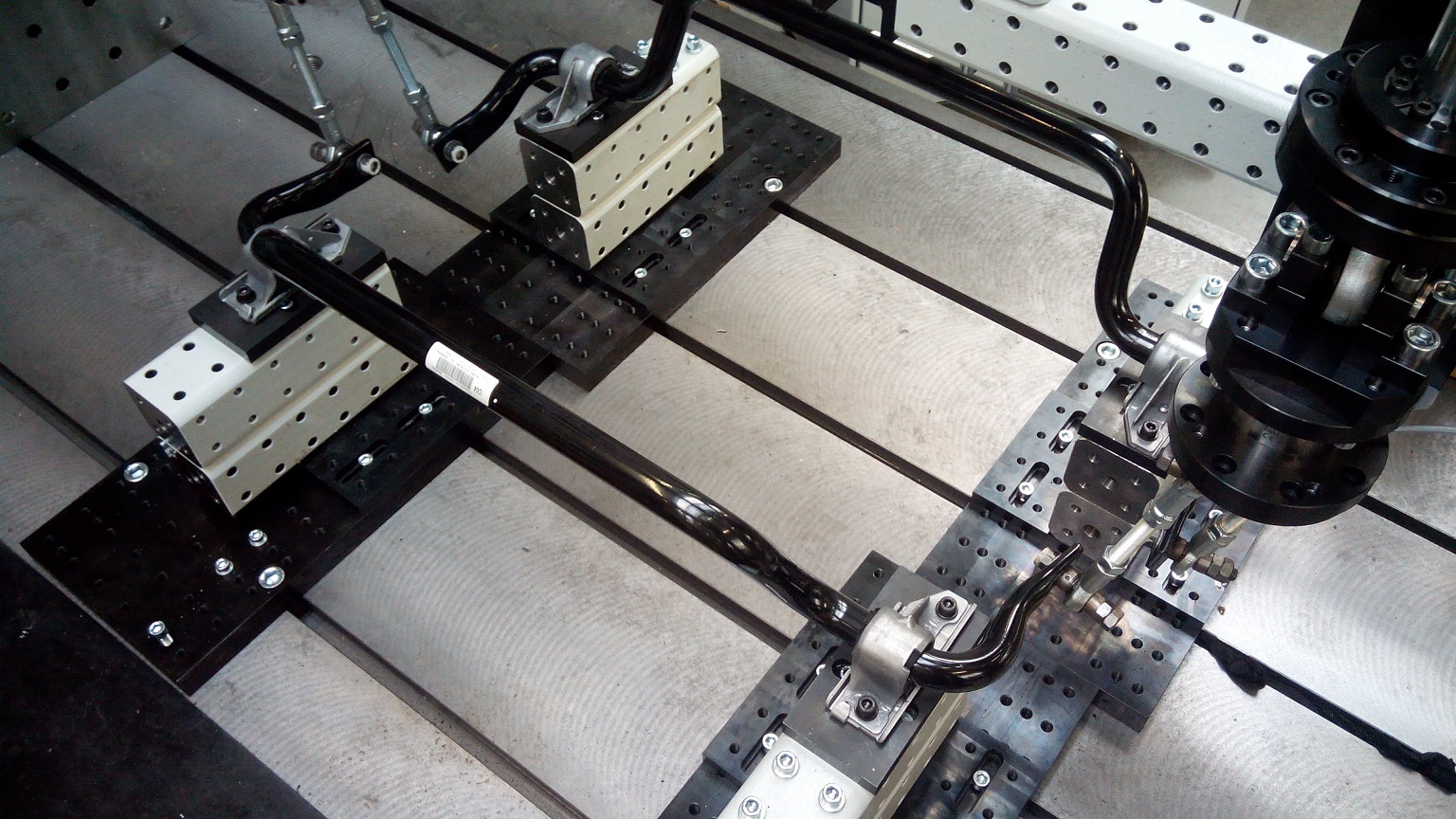

- Clamping foundation as base plate: The base plate is made of cast iron with steel additive. Lengthwise, T-slots for screws are applied. Using appropriate T-slot nuts, various structures can be realized. These T-slot nuts are pushed into the T-slots of the clamping plate at the desired position. In order to ensure the highest possible stability of the plate, a special casting process is used, guaranteeing the greatest possible stress-relieved casting. In addition, the ribs at the end are reinforced in a T-shaped way. The clamping plate is vibration-isolated and level-regulated by means of pneumatic bellow cylinders.

- Load generator designed as a chain: 2 hydraulic testing cylinders with integrated displacements sensor, servo valve and hydraulic fluid storage, 2 joints

The upper joint is equipped with an adapter plate for connection with the cross beam. It can be adjusted continuously in cross direction. The load cells are adapted to the testing cylinders. - Power generator (hydraulic unit with housing): A hydraulic unit, which has been especially developed for the demands of the servo-hydraulic testing technology, is used.

- Control, including software

- Specimen clamping and adaption: The clamping device is the connection between specimen and base plate. It introduces the test forces (and their reactions) into the base plate. The adaptations mainly consist of elements of the construction kit system SPR100. Using appropriate adaptation, two stabilizer bars can be tested at the same time. There are various types of testing rig designs. For instance, the testing rig can be prepared for using a testing rocker.