Second-hand Machines

As good-value alternative, we always offer renewed second-hand machines.

As good-value alternative, we always offer renewed second-hand machines.

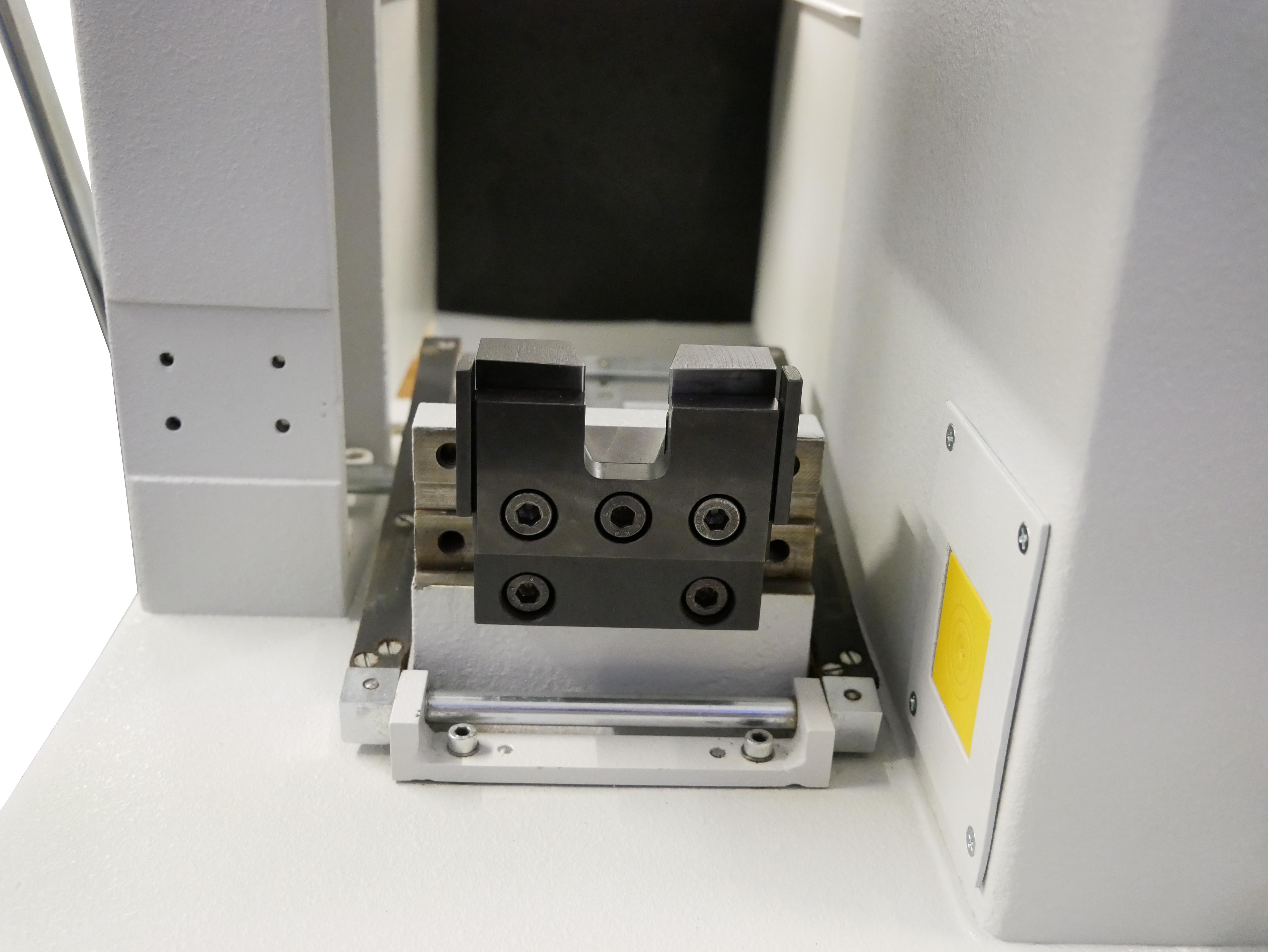

Anvil 4 x 3 x 27 mm

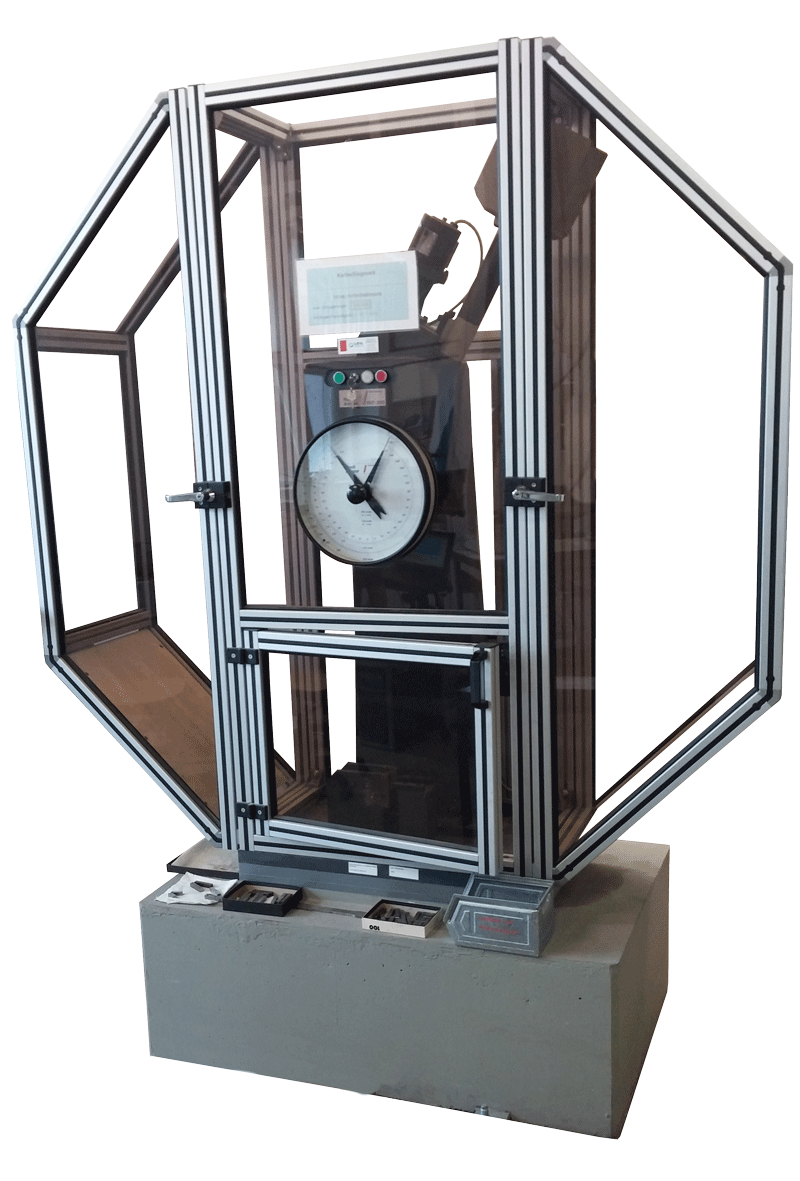

The pendulum impact tester corresponds to the technical conditions of ISO 13802 and DIN 51222.

The device is second-hand, refurbished, checked and in good condition (year of construction 1999)

The pendulum impact tester consists of the basic unit with:

The pendulum impact serves for Charpy impact tests according to ISO 148-1.

The device is used and in very good condition (year of construction 1995).

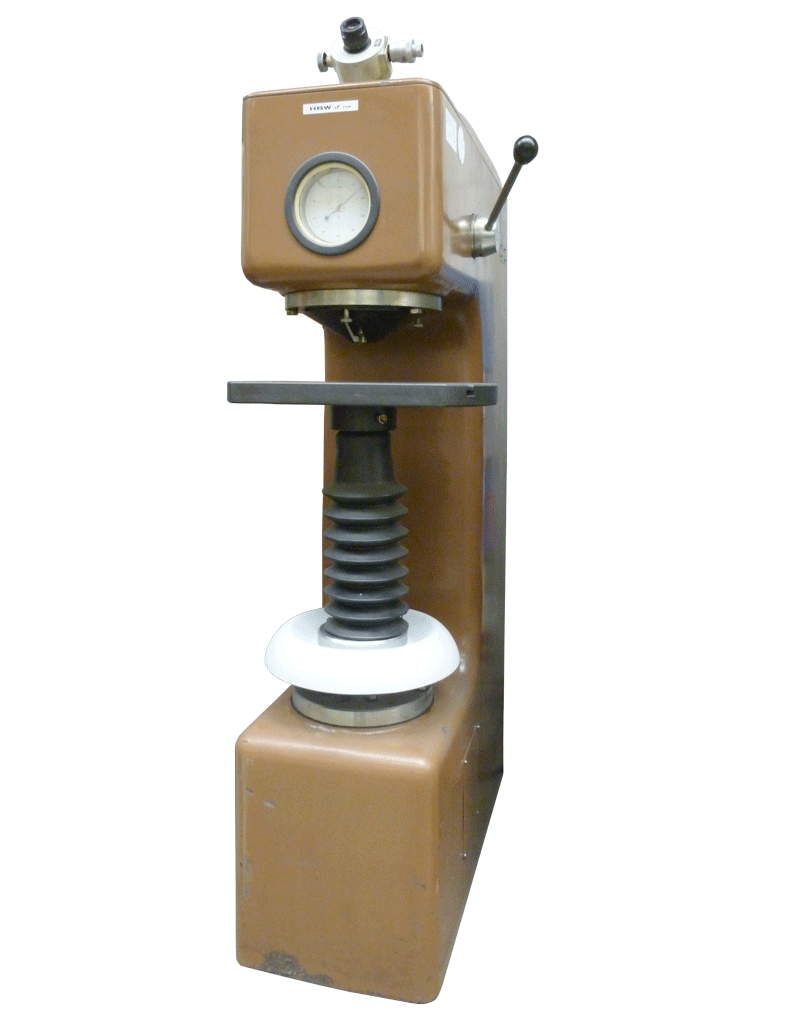

The hardness tester HPO 250 is a desk device to determine the Brinell and Vickers hardness of steel and metal of all kinds.

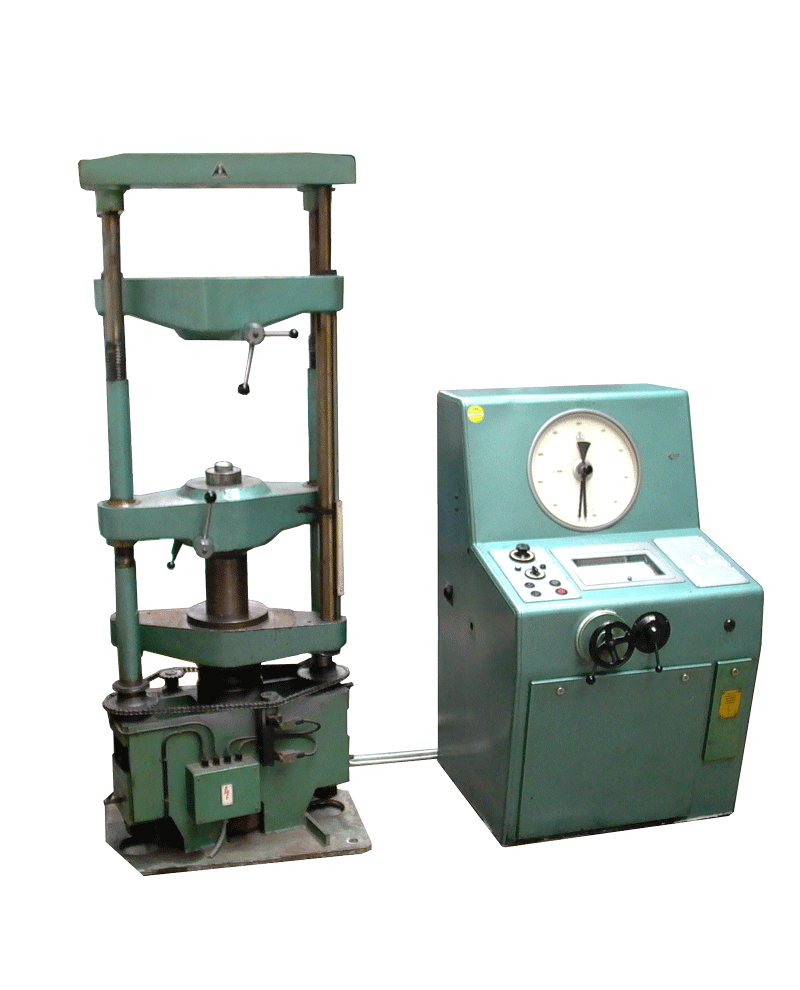

The hardness tester HPO 3000 is a floor-mounted device to determine the Brinell hardness of steel and metals of all kinds according to ISO 6506-1. It corresponds to the standards DIN 51200 and ISO 6506-2.

The machine is used to determine the tensile, compression and bending strength of materials, such as steel and metal as wires, rods, plates, pipes, as well as plastic and wood. Thanks to ist large-room design, the testing machine can also be used to test construction components. The testing machine corresponds to the requirements of DIN 51221.

The machine is refurbished and technically in good state.