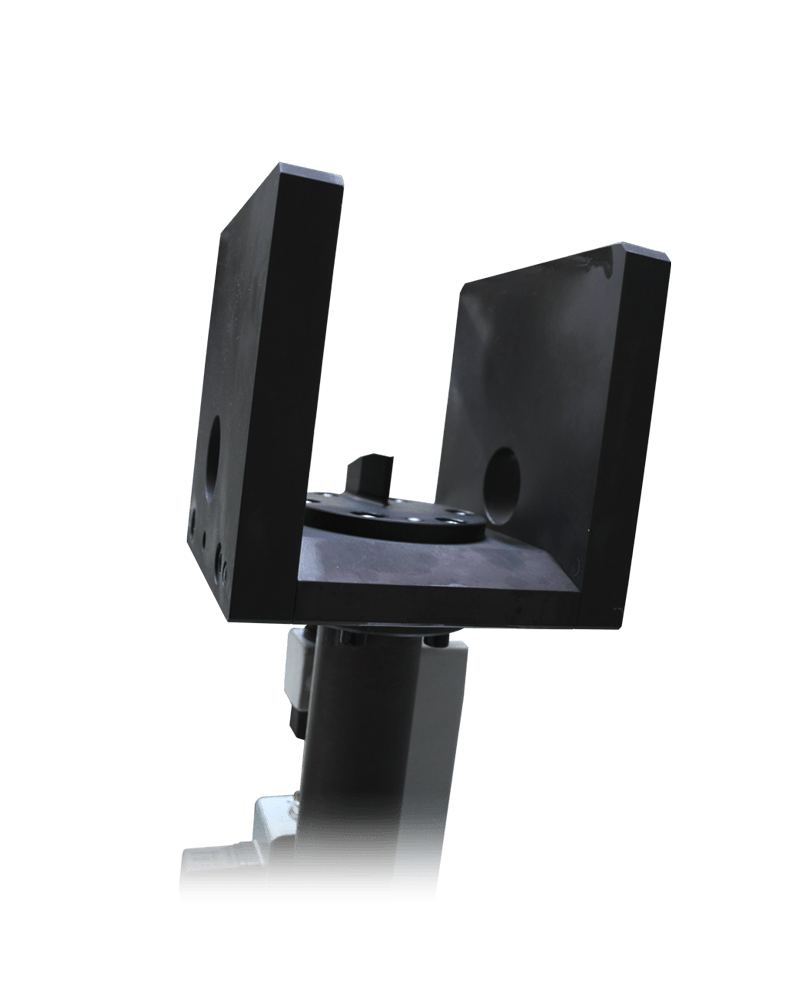

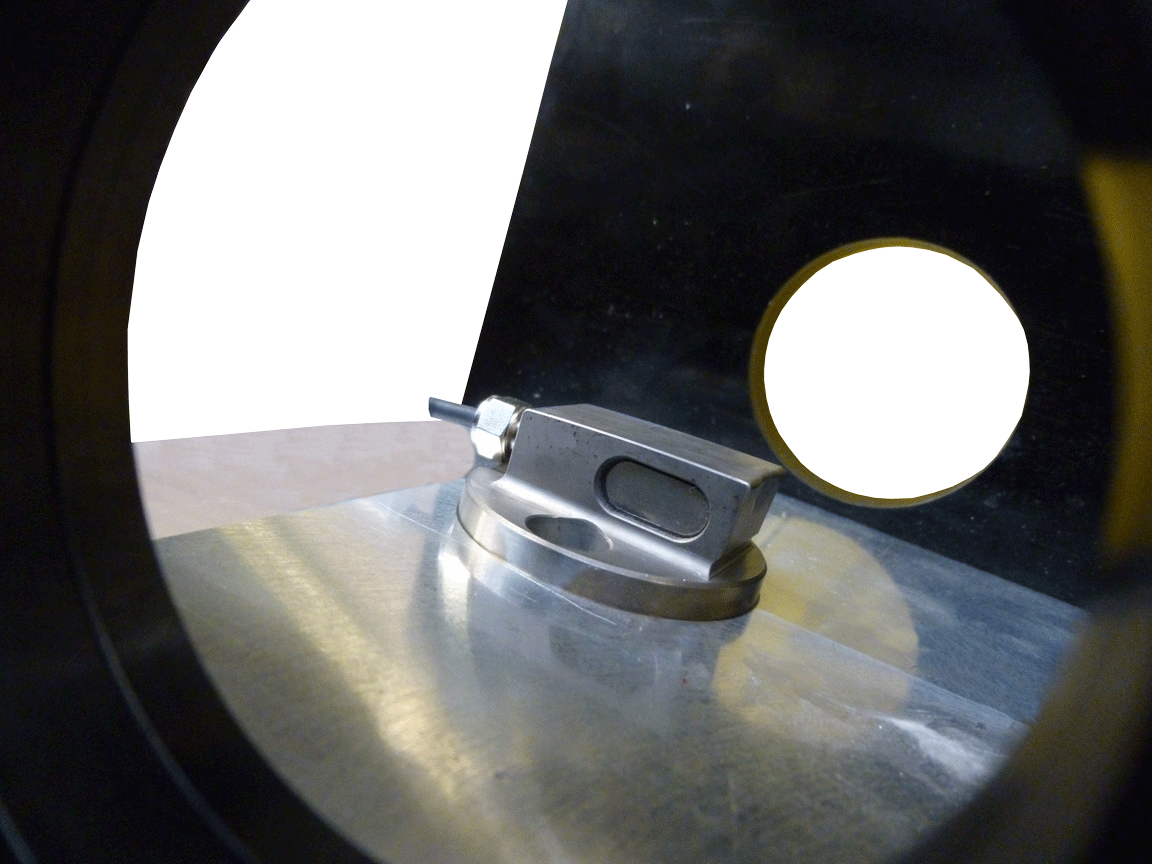

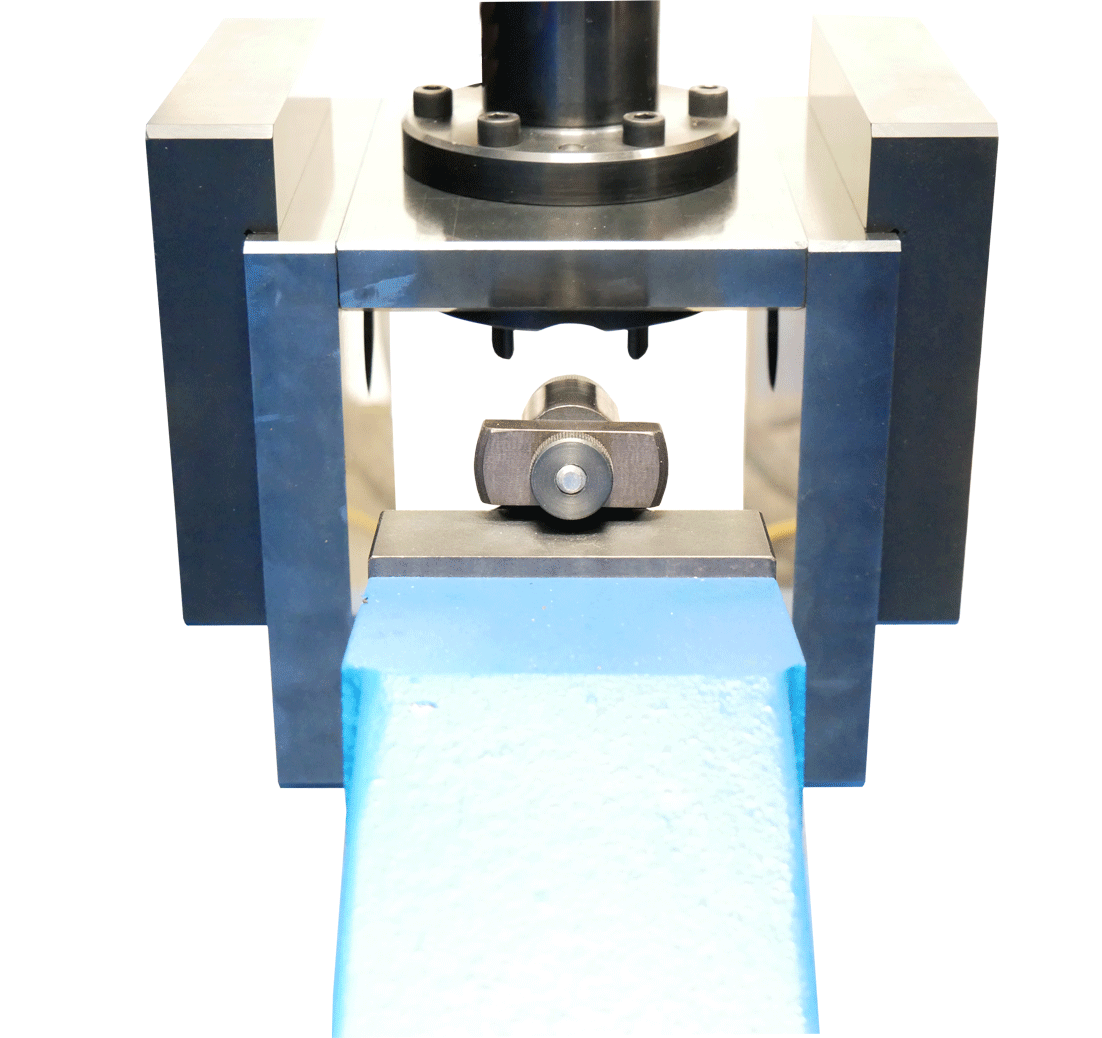

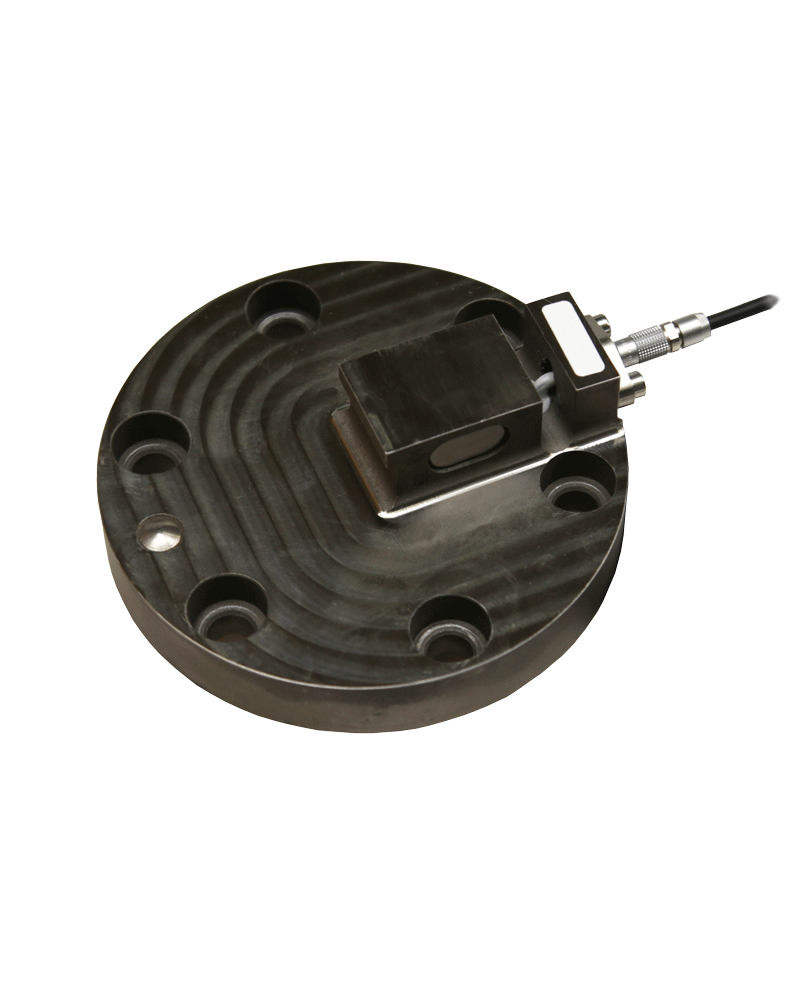

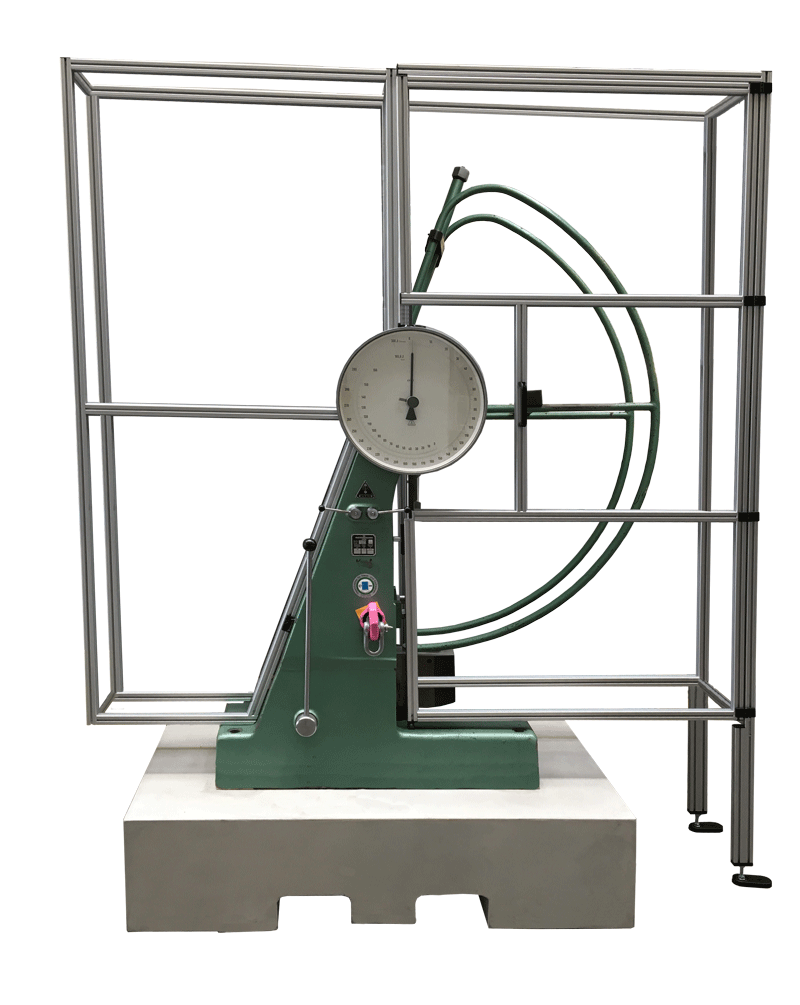

Pendulum Impact Tester

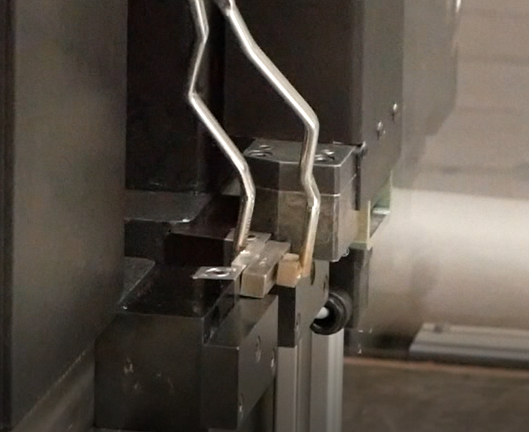

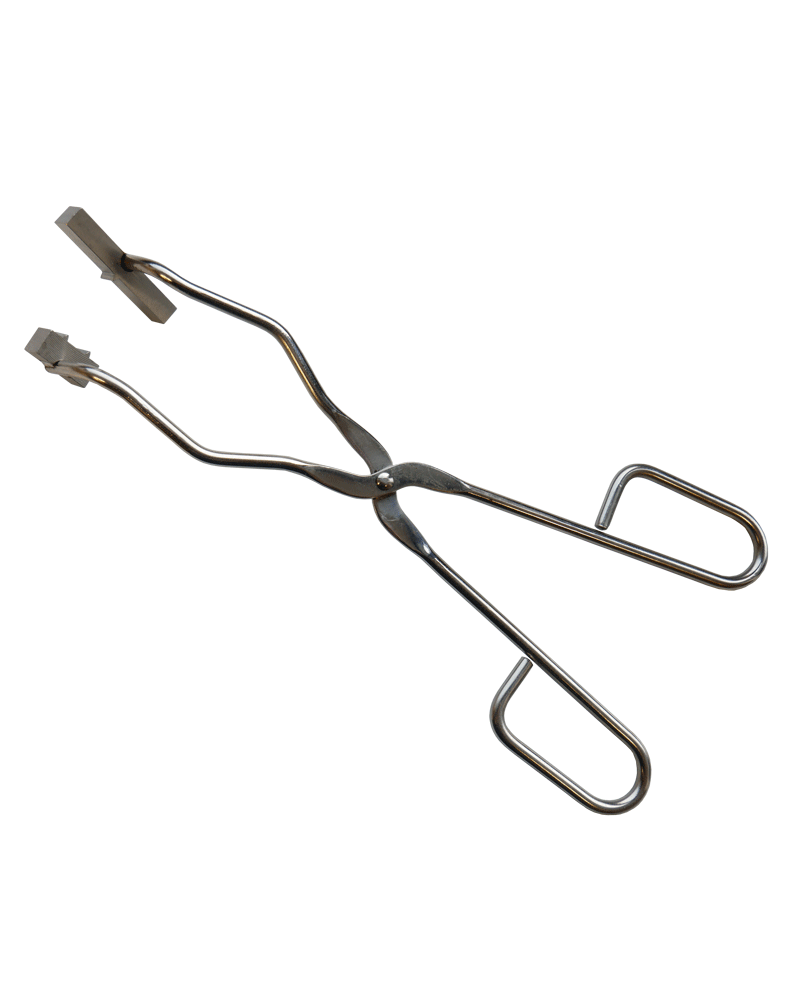

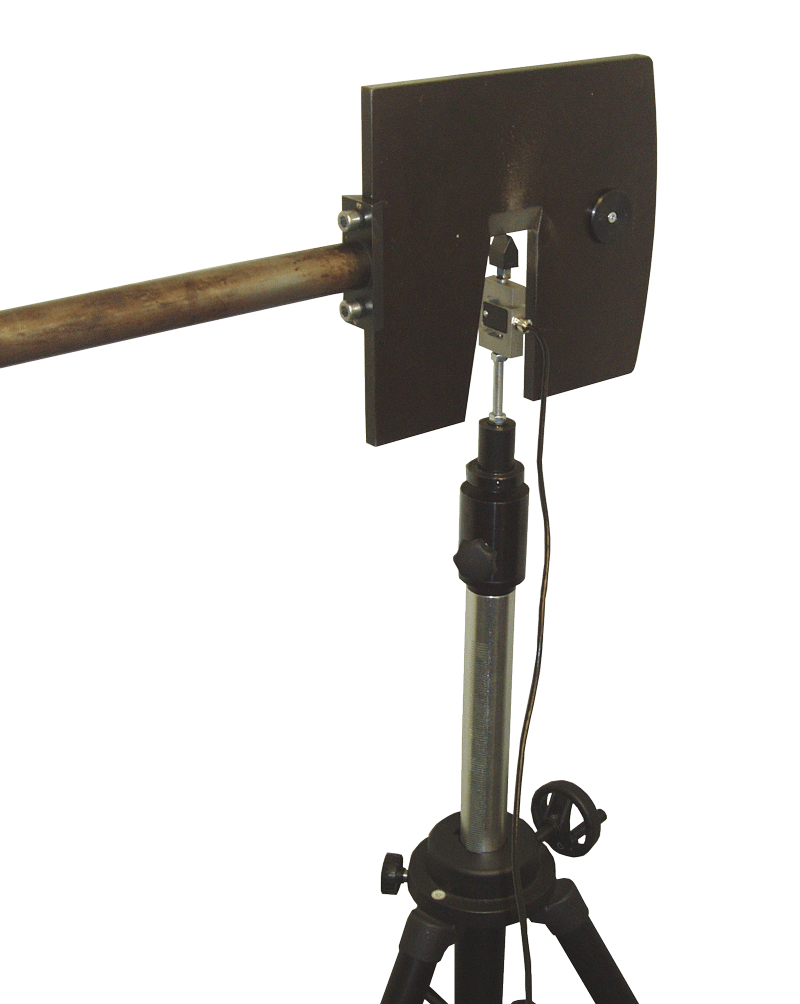

Charpy and Izod

and more

The technology of WPM pendulum impact testers is up-to-date. Their stable design guarantees impact tests with very low vibration and high measurement accuracy.