Testing Rigs for Railway Technology

Whether you want to test railroad switches or springs - we are your partner for quality and safety in railway technology.

Whether you want to test railroad switches or springs - we are your partner for quality and safety in railway technology.

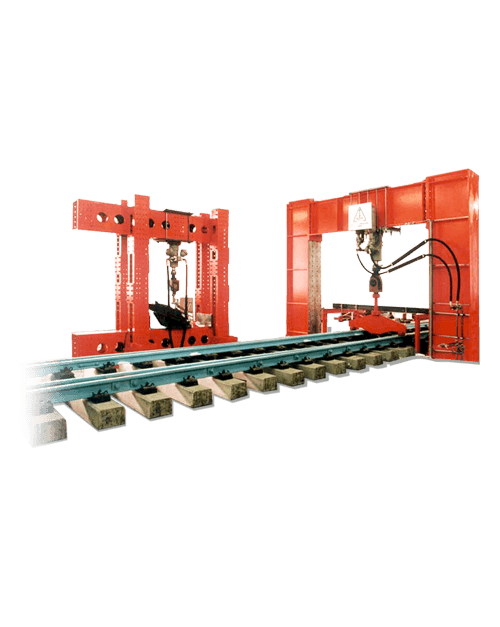

The servo-hydraulic testing rig for railroad switches serves to examine the elastomer-dynamic behaviour of railroad switches with high driving speed.

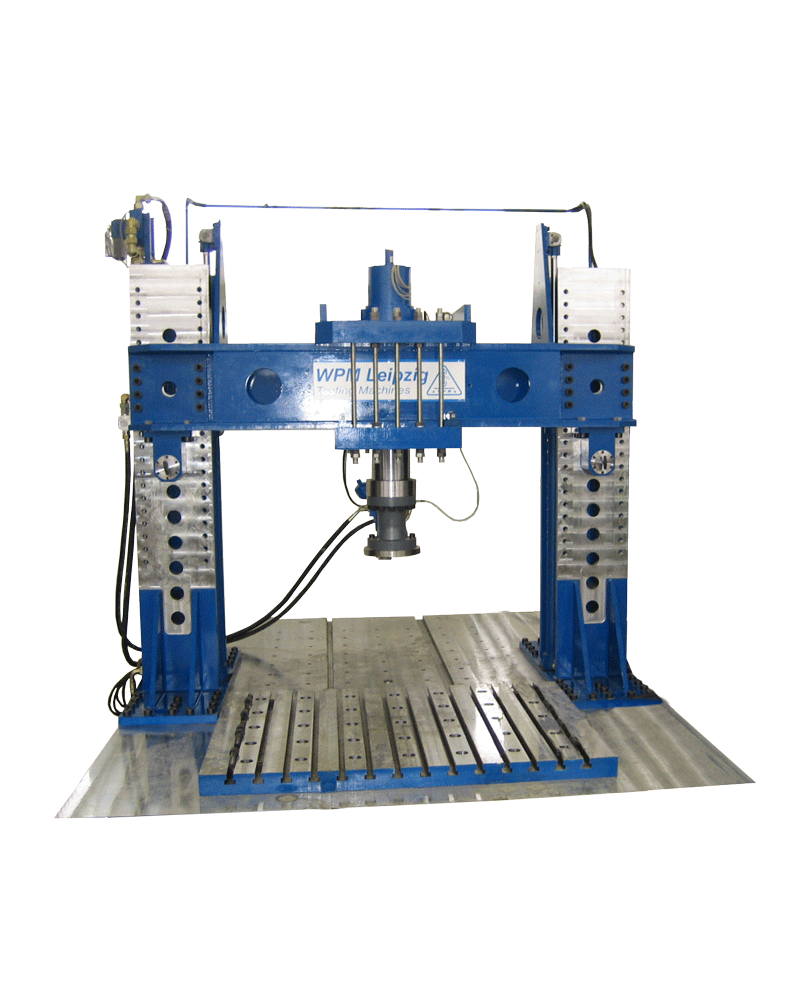

This testing machine is designed for pressure and tension loading of specimens in different design and size.

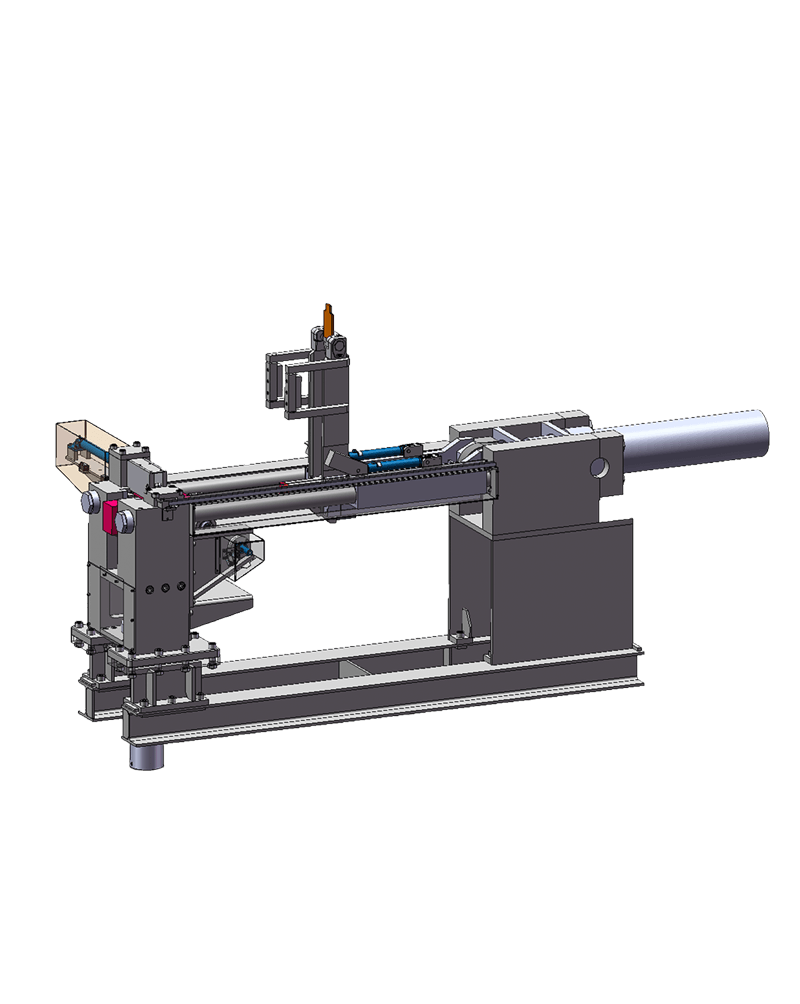

The spring collar remove press of WPM serves to disassemble regenerative leaf springs of trains. The press can be used for leaf springs with a total length of 1800 mm at maximum and a width of 60 mm, 90 mm and 120 mm.

Forces of the wedge on the spring:

Lifting the spring assembly:

Production throughput in continuous operation: 50 springs per shift

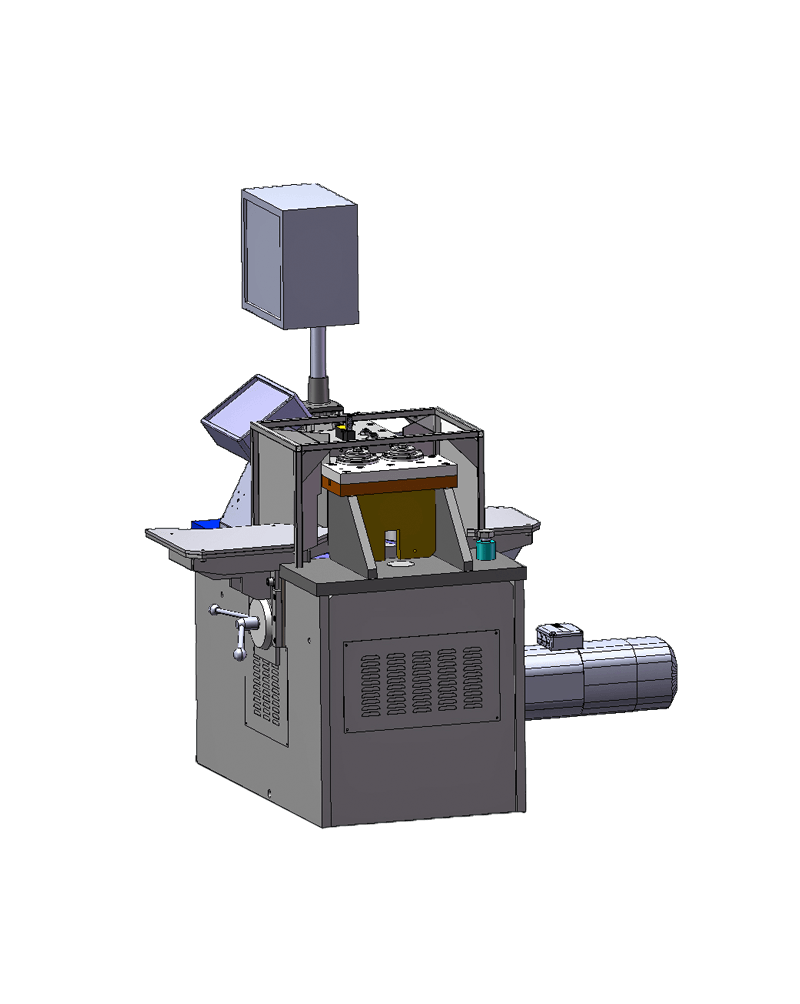

This machine serves to rework the spring layers of leaf springs used in landing gears of track or road vehicles.

The spring leafs are rolled to achieve the desired bend and spring pre-load. Afterwards, all sping leafs are assembled to a complete spring.

Two rollers mounted in anti-friction bearing, which are driven by a gear motor with a brake, are in a frame. On the other side of the rollers, the pressure roller mounted at a slide, is situated. The hydraulic cylinder moves the slide and produces the necessary bending force. This is a friction-less driven differential cylinder with leakage-free sealing.

The spring testing machines of WPM are used for quasi-static tests of screw and leaf springs.

The following tests can be carried out: