Drop Impact Tester

The drop impact testers are designed to carry out Charpy and Batelle drop weight tests on metallic materials.

The drop impact testers are designed to carry out Charpy and Batelle drop weight tests on metallic materials.

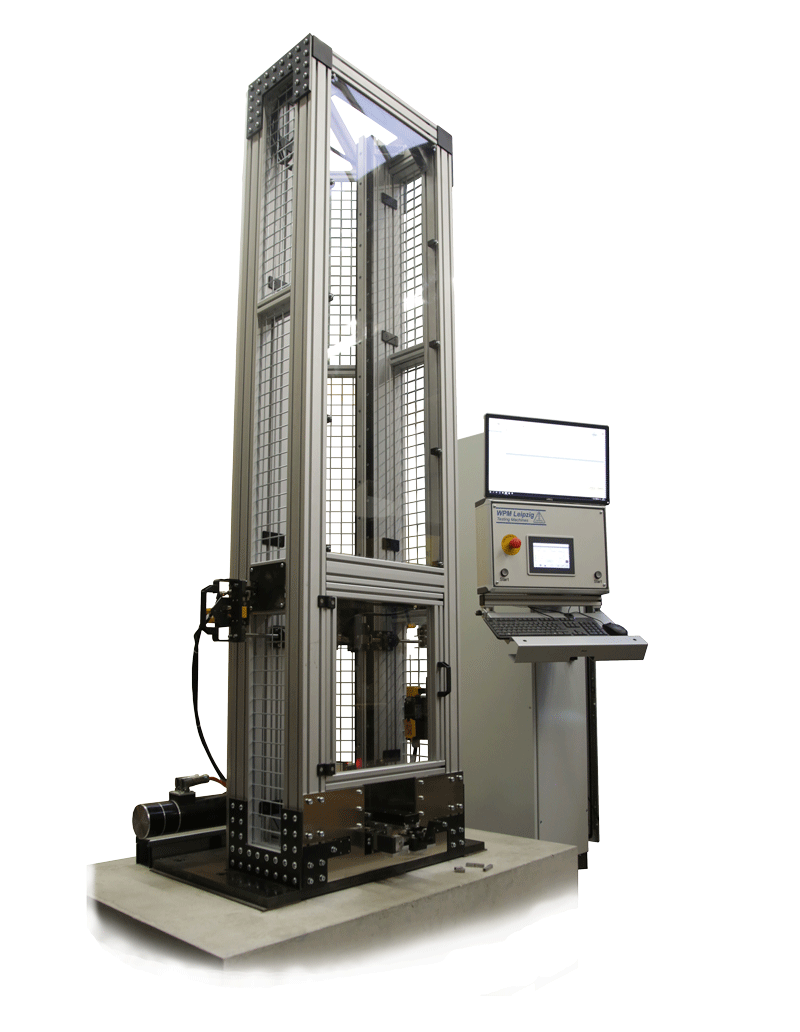

The drop impact tester FWi150 with instrumentation was designed to carry out Charpy impact tests at notched metal specimens (according to ISO 148, ASTM E23 and GOST 9454). A striking edge mounted on a double-side guided drop assembly shatters the specimen. The energy of the FWi150 depends on the selected drop height and the corresponding drop weight.

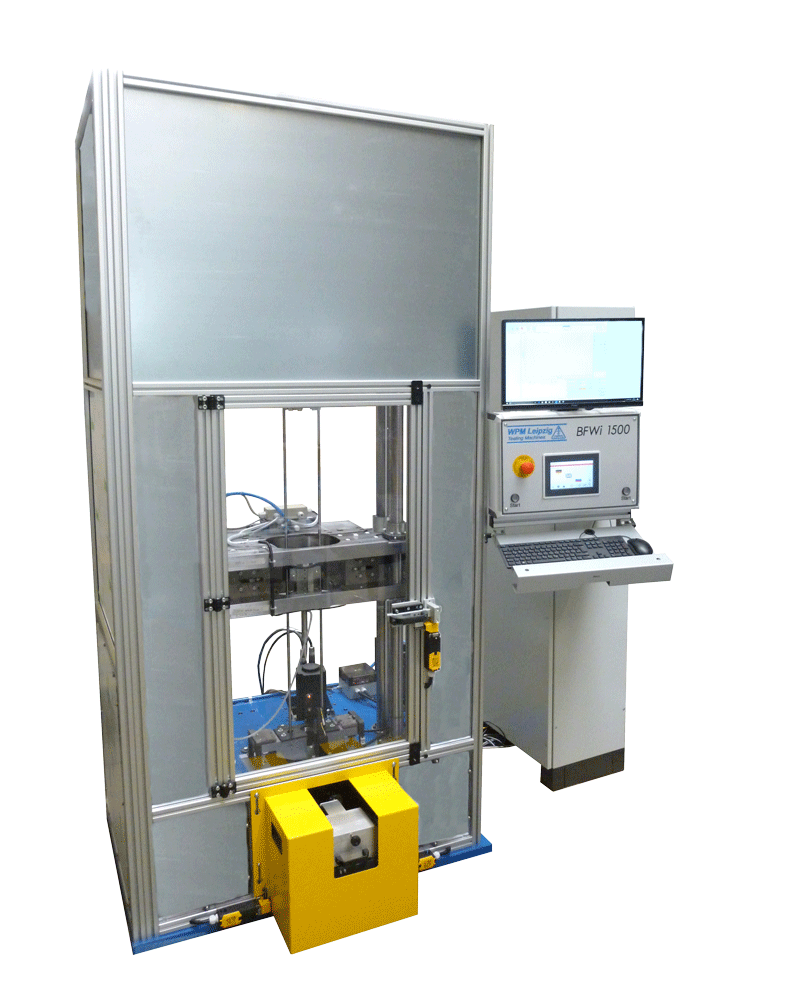

The drop impact tester BFWi 1500 especially serves to carry out Charpy impact tests at standard metal specimens notched at one side according to ISO 148, ASTM E23 and GOST 9454. However, other drop impact tests can be carried out, as well.

| Without acceleration | With acceleration | |

|---|---|---|

| Drop weight | 3.0 to 7.5 kg | 4.0 to 7.5 kg |

| Drop height | 0.075 to 1.0 m | highest simulated drop height 20,4 m |

| Drop velocity | 1.1 to 4.43 m/s | 20 m/s at maximum |

| Drop energy | 1.1 to 73.5 J | 73 to 1700 J |